Adopt our Useful Tips

The useful tips hereunder are merely suggestive and it is a responsibility of the professional that applies the products to verify onsite which is the best solution.

Paving Bases

Light Use – 25mm layer of compacted sand laid over compacted sub-soil.

Medium Use – 25mm layer of semi-dry concreting sand and cement mixed in a 5:1 proportion laid over compacted sub-soil.

Heavy Use (Vehicle) – 100 – 150mm hardcore sub-base blinded with sand laid over compacted sub-soil. Then a 25mm layer of semi-dry concreting sand and cement mixed in a 5:1 proportion.

Drainage

Standing water and permanently wet sub-bases can cause staining so Patios should always be laid with a slope to drain off rainwater. This slope (away from buildings) is normally a drop of 25mm for each metre length – but a more gentle 10mm for each metre is less noticeable and will still enable water to drain off. Additional measures may be required where drainage is a particular problem.

Ground Preparation

Remove top soil from the area to be paved. For heavier loading some form of sub-base must be used, this may require the excavation of some sub-soil.

De-icing Salts

De-icing Salts and aggressive acids should not be used on Fabistone paving.

Storing Paving

Storing Paving

Always stand paving on edge to avoid surface scratching.

Construction

Mortar Mix

Paving slabs should be bedded on 5 generous spots of mortar. 1 part cement to 5 parts building sand.

To make a good concrete or mortar mix use well-mixed and clean ingredients and clean water. The proportions should be accurately measured, using a bucket.

Mixing concrete and mortar can stain materials and contaminate soil. Use a large smooth ‘board’ as your mixing surface. Only mix enough for twenty minutes work.

Laying Paving

Slabs should be laid onto 5 generous spots of very workable mortar so that on pressing into place the mortar displaces to occupy almost the entire under surface of the slab ensuring good support on compression. The ‘spot’ method makes accurate and even slab laying easier but on completion needs to be protected from pedestrian use for 1 to 2 days.

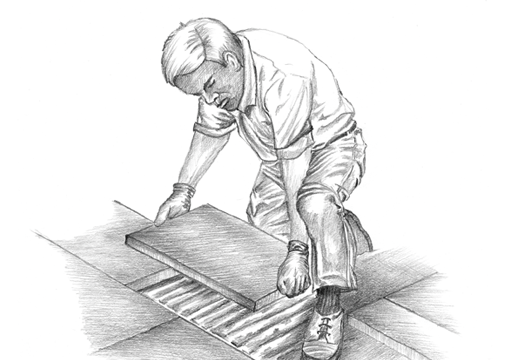

Cutting

Paving slabs may need to be cut. This can be achieved, either by cutting with a mechanical guillotine or angle grinder, or by using a chisel and hammer. A flat, level area is needed for this. The slab is marked all around with a pencil.

Use firm but short blows on the chisel. Several passes may need to be made.

Then, a thin piece of timber 5mm thick is placed under the slab. Several sharp blows with the handle of the hammer will usually split the slab cleanly.

Jointing

Fabistone Paving should be pointed with a joint up to 10mm wide according to the style. This may be increased to 15mm on Fabistone Paving because of the irregular fettled edge on these products

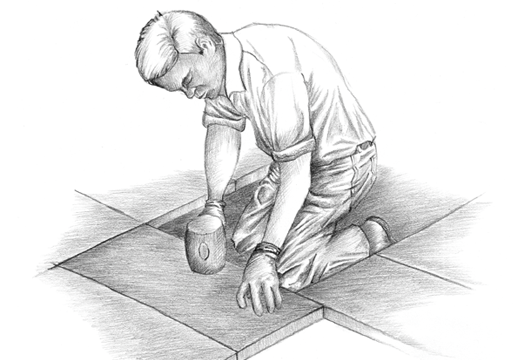

Pointing

Pointing

After laying the paving pointing can be carried out. The quality of this pointing work is important.

Make up a semi-dry pointing mix 1:3 cement : sharp sand. Take the mix to the joint on a large trowel. Using a slightly smaller pointing trowel, the mix is ‘chopped’ into the joint. Great care must be taken to keep the paving free from cement stains. The pointing trowel is then used to push and compact the mortar and to clear any remaining surface mortar particles. The finished joint should have a smooth shallow concave shape

Efflorescences and claims:

This phenomenon might appear in some paving and walls. Fabistone cannot be responsible for it, as it´s a normal chemical reaction for good quality products with high cement content. The phenomenon may be exhibited by an apparent loss of intensity of the colour and the appearance of a milky white bloom on the face of the product. The effect generally disappears with time and is in no way detrimental to the performance of the product.

THE COSTUMER HAS TO BE WARN at the moment of the purchase. Fabistone will not take any responsibility for claims based on this efflorescence phenomenon.